Tuning - Part 2 - 11/06/2015

In the continuing saga of tuning, time to get more baseline info and look at why the car runs so poorly.

Distributor cap removed to inspect the rotor and weights.

Weights are extremely gooey and sticky, the assembly doesn't move much at all.

Center plate and weights are removed and plenty of PB Blaster sprayed all over the assembly. It now moves freely.

045 weights and a 381 center plate. Per the books this is a combination for 8 distributor degrees (16 at crank). In order to get 34-36 total degrees at the crank, the initial with this has to be set at like 20-22 degrees, which is extremely high (12-14 is where I tend to find most of the engines I have wind up). Not exactly optimal as the HC count will go up and it will want to run lean...

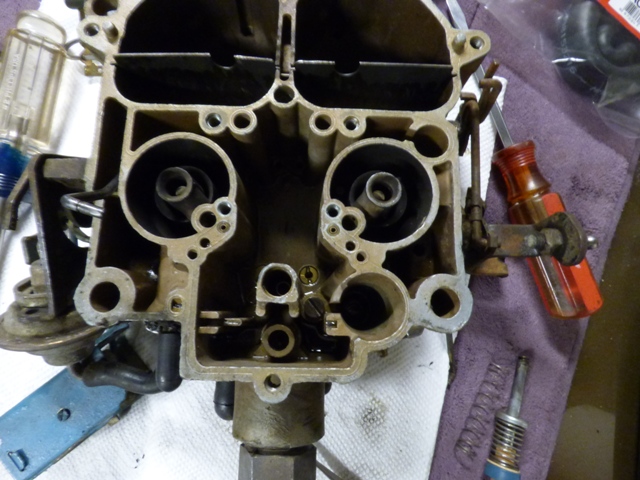

Time to remove the carb, need to find out what's inside.

Kind of gooey.

And naturally the metering rod and power piston assembly is bent up pretty good. Means the passenger side will run considerably leaner than the driver's side as the needle will never go down on that side as it is bent up.

All cleaned up. Primary rods in the carb are 45B, jets are 71, and secondary rods are DA. An entire can of brake cleaner was used to clean out the various passages, along with a paperclip and some solder to wire out the smaller ones.

Power piston is now unbent.

And ready to put back on and run the engine again!

After running it for 5 minutes, during which it fired up nicely and even ran pretty smoothly, it up and died. Pulled cap and found the rotor had broken. Never seen this before...

Well, parts stores are closed so it's off to get another rotor tomorrow. Then finish re-checking timing and verifying carb tuning.

Return to 1967 Executive Wagon

Last updated November 6th, 2015