The New Engine - Part 1 - 08/02/2008

Wow. Many moons have passed with nary an update. I bought a new driver, I fixed it's front end, and put this car on the backburner. Although my disassembly of the 455 was probably more cause for holdup than anything else. Every cylinder had a HORRID ridge in them. It would need to be bored. In my disassembly I completely botched it and gouged two of the cylinders, bad enough to need sleeving. I am a complete idiot. My spirits were low and prospects for completion were really low. I was whining to Steve today and he said "maybe I've got an engine laying around we can work with." He keeps suggesting this monster 326, but my main concern is related to motor mount issues. Paul has a 400 that someone removed the pistons and rods from (why?) and we found another 400. A 1972 400 with pistons and crank all set up and potentially ready to go.

The new engine! It's an interesting block. Steve pulled it out of a 1962-1963 Buick convertible that had been sitting in the dirt and grime for at least 10 years. This was back around 2002. The crank spins, no noise, but the cylinder walls are nasty and need cleaning. Then we need to inspect the pistons to make sure they are good along with the rod and main bearings.

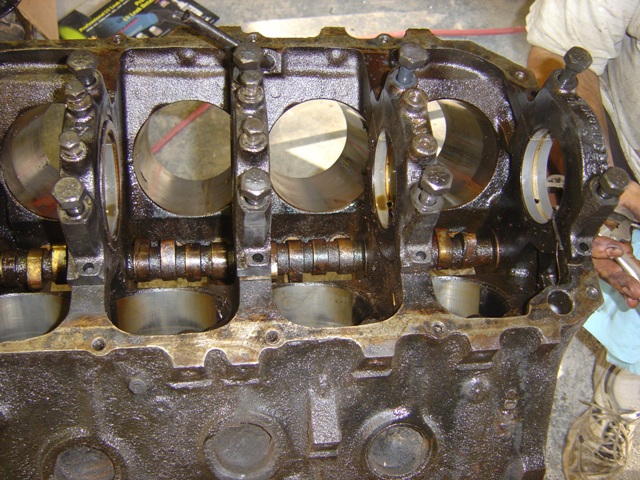

Cleaning with the wire wheel. The cylinders come very clean actually. Standard bore with VERY little ridge, indicative of low miles. Everything appears to be factory. No pitting in any of the cylinder walls either.

More cleaning. Gotta do it, this is actually the hardest and most tedious part of an engine - cleaning it up. It's gooey, but not overly nasty like the Lemans 350 replacement was.

Lots of PB Blaster and WD-40 to clean and lube everything up. The crank spins great half the time and is a bear to move the other half.

An AC Delco fuel pump that has screws to rebuild it with... I've never seen one of these before and have no idea how old it is. It's a conversation piece more than anything really.

Harmonic balancer and timing cover. Timing cover is completely rotten and junk. Water pump seized up too. Balancer looks pretty nice still.

The coolant passages are... crusty. Badly. Seriously. Chunks fell out. Don't believe me?

Yeah, lots of chips and chunks of crap. Lots of pine needles too (funny, no pine trees anywhere near Steve's place).

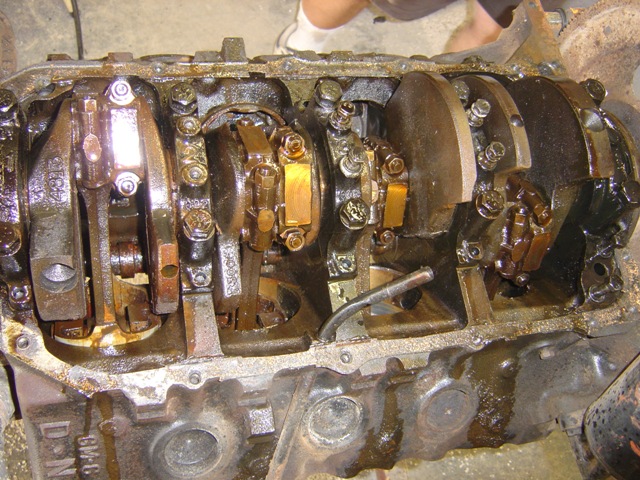

We pulled the #5 piston and rod because we wanted to find out what was holding the engine up. It turns out that the middle rings are all seized and the rest of the rings have zero spring left in them. Ah well, re-ring time.

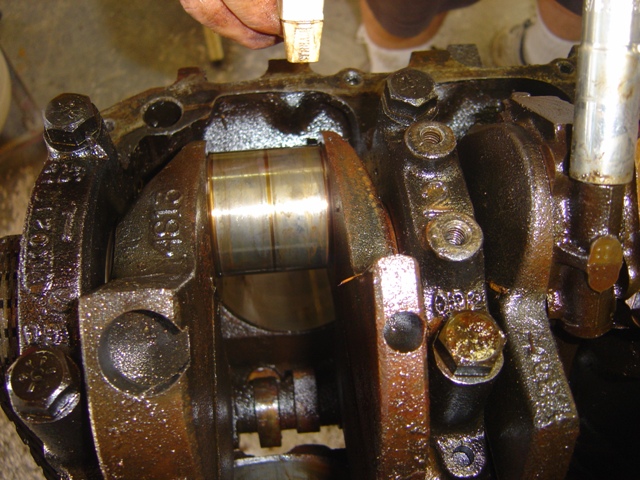

The bearing is all shiny in the middle and nowhere else, which is usually a sign of detonation. Not apparent on the crank though and the rod looks good.

Crank looks good. No ridge at all. Hopefully it will clean up with just some polishing and not need to be turned.

Crank on left, 455 crank on the right. Nifty to see the bigger journal and bigger counterweights on the 455 vs. the 400.

Pistons and crank all out. Cam needs to come out. It's pretty gooey. And worn about 0.003" on the exhaust lobe of the #7 cylinder. Junk cam! Steve has a Melling RAIII grind (one of the better factory grinds for a 400) which is the same cam I put in the Lemans (which runs stellar). Steve also has some 6X-4 heads that are machine shop fresh I am trying to score for a decent price (make a W72 clone of this engine!).

Pistons are all boxed up for safekeeping. Still oiled too. One piston fell and the outer step on one of the ridges skirt cracked off. The piston itself seems to be fine, no apparent foul as this little area is not part of the combustion chambers. I can get a "new" piston with 8 valve reliefs in it from Badger... but why?

Block all stripped and coated in PB Blaster and WD-40 to get all of the crud and gunk out of it. The block drains required a hammer to clean out the crud in them. Threads are chased and petcocks will be installed.

Block bores are in pretty good shape.

This is hopefully going to be a very cheap alternative to getting the 455 redone (no machine shop work outside of Beans Crankshaft cleaning up the crank and supplying new quality bearings). The transmission will also need to come out to be rebuilt, but we're going to tackle it at Steve's place. I've got books and drawings and Steve should have no problems pointing out what is wrong or screwed up with my work. Victory will be mine (some day one day). Steve is also now into AC setups and installations, so we can now repair all of our AC systems! Score one for the good guys!

Return to '75 Trans Am Page

Last updated August 2nd, 2008